If you are going to build robot hardware, it is important to choose the right robot components. It will be good if you have read my previous post about robotics, different types of robots and choosing the right robot sensors. These posts will give you a fundamental concept of robots, robotics, and sensors.

In this post, you can see a quick way to choose the right actuators/motors for your robot. There are different categories of robot actuators, you can see an introduction of different kinds of actuators used in robots first and then you can see which type of actuators can be used in different kinds of robots. This will help you to choose the right actuators for your robot.

1. Different types of Robot Actuators

The robot actuators can classify based on how they move the output motor shaft and which energy they transform to make the move. According to the movement of the actuator shaft, we can simply classify the actuators as

- Linear Actuators: The shaft of the linear actuators will only move in a linear fashion.

- Rotary actuators: The shaft of the rotary actuator will only rotate in an axis.

The linear and rotary actuators can be classified based on the energy they use to move the shaft of the motors. Here is a list of actuator classes that use different energy to create movement.

1.1 Hydraulic actuators

The hydraulic actuators are used in robots handling heavy loads. These actuators can produce very high force if we compared them with other actuators. These actuators are deployed where higher speed, accuracy, and stability are required.

These actuators have a cylinder and piston arrangement which is shown in the following figure. The chamber is filled with hydraulic fluid. The pressure applied to the fluid will push the piston, and that will move the actuator output shaft. The hydraulic actuators can convert the piston movement into linear and rotary movements.

1.1.1 Advantages of Hydraulic actuator

- Easy to control and accurate

- Simpler and easier to maintain

- Constant torque or force regardless of speed changes

- Easy to spot leakages of system

- Less noise

1.1.2 Disadvantages of Hydraulic actuator

- Proper maintenance is required

- Expensive

- Leakage of the fluid creates environmental problems

- Wrong hydraulic fluid for a system can damage the components

A common example of a hydraulic actuator system: JCB

The Boston Dynamics WildCat robot is one of the example robot working with hydraulic actuators.

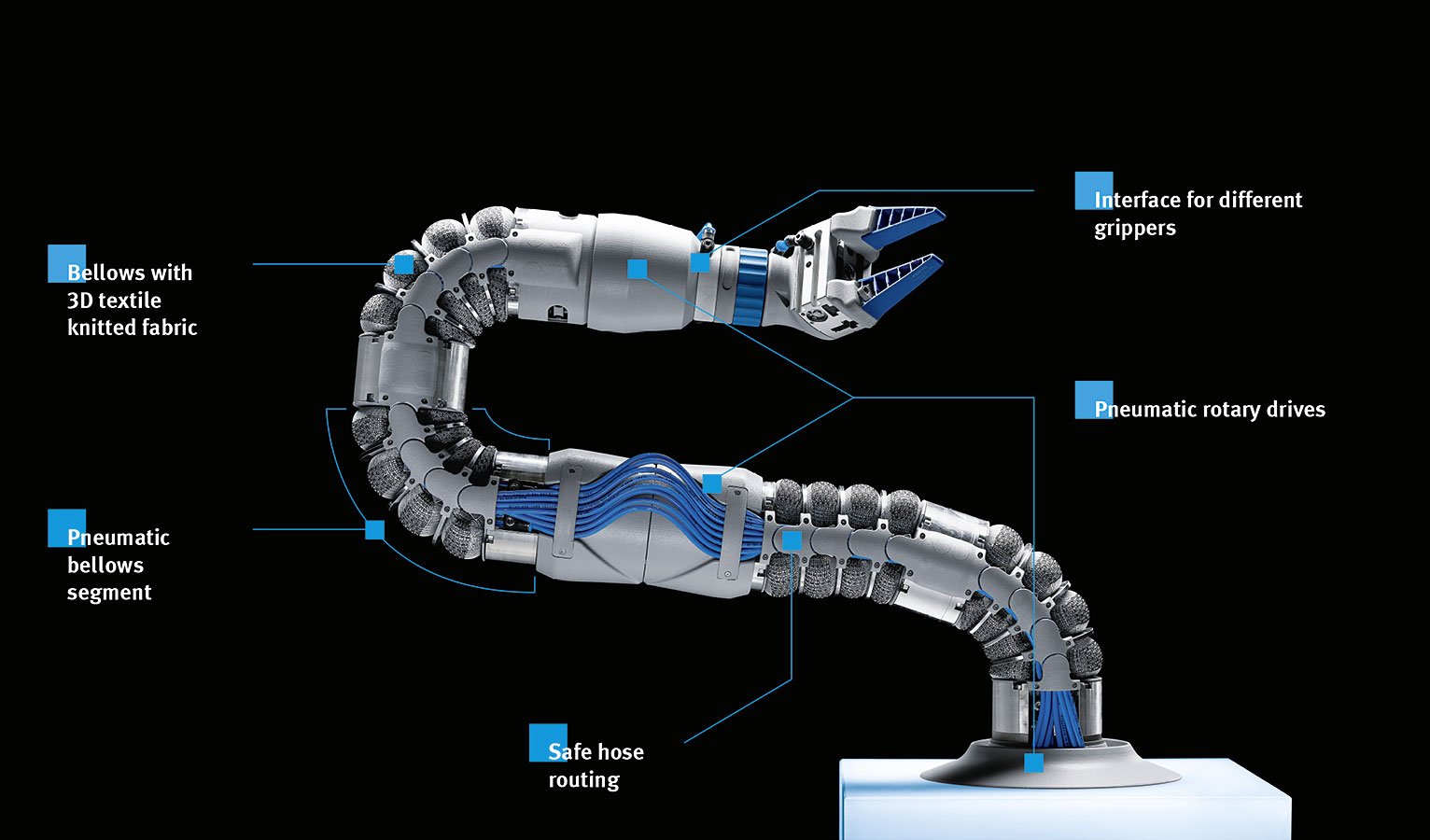

1.2 Pneumatic actuators

As you have seen in hydraulic actuators, they use a hydraulic fluid in the cylinder in order to move the piston. The pressure applied to the fluid will move the piston. But in pneumatic actuators, instead of hydraulic fluid, compressed air is moving the piston.

Similar to hydraulic actuators, it can produce linear and rotary movements.

When compared to hydraulic actuators, here are the advantages and disadvantages of Pneumatic actuators.

1.2. 1 Advantages of Pneumatic actuators

- Clean, less pollution to the environment

- Inexpensive

- Safe and easy to operate

1.2. 2 Disadvantages of Pneumatic actuators

- Loud and noisy

- Lack of precision controls

- Sensitive to vibrations

Here is an example of a bionic soft arm robot that is made of Pneumatic actuators. The robot is made by a robotics company called Festo.

Here is the video of BionicSoftArm

1.3 Electric actuators

The commonly used actuators in robotics are electric actuators. This actuator converts electric energy into linear or rotary motion.

The electric actuator can be AC/DC actuators. Mostly, robots are using DC actuators.

Here are the advantages and disadvantage of electric actuators

1.3.1 Advantages of electric actuators

- These actuators offer the highest precision among other actuators.

- It can be easily network and can easily program. They offer immediate feedback for diagnostic and maintenance.

- They provide complete control on motion profiles and can include an encoder to control the velocity, position, and torque.

- Less noise compared to hydraulic and pneumatic actuators

- No fluid leak, so fewer environmental hazards.

1.3.2 Disadvantages of electric actuators

- The initial cost of the electrical actuator is higher

- Unlike pneumatic and hydraulic actuators, these actuators are not suitable for all environments.

- There are overheating, wear and tear issues are there compared to pneumatic and hydraulic actuators.

- The actuator’s parameters are fixed, so to change torque, speed, etc to a different level, actuators should replace.

1.3.3 Different types of DC actuators

Let’s see different types of DC actuators used in robots.

1.3.3.1 DC Motors: A dc motor will have ‘+’ and ‘-‘ negative terminal. The output of the dc motors shaft will start to spin if we supply DC voltage to the motor terminals. The speed of the motor shaft can be adjusted based on the voltage across the motor terminals.

Here are some examples of DC motors that you can buy.

1.3.3.2 DC Gear Motor: Adding a gearbox on DC motors can increase the shaft torque and reduce the motor speed. DC Gear motors consist of a DC motor attached with a gear system with an output shaft.

Here are some examples of the DC gear motor that you can buy

1.3.3.3 Servo Motors: The servo motors consist of a DC motor plus gear system plus a servo control circuit. The servo control circuit can able to rotate the gear shaft with a specific angle. The computer inside the robot can command the servo motor to rotate at a specific angle using PWM signals. There are different types of servo motors, the normal servos are called RC servos. There are analog servos and digital servos. Normal RC servos are analog servos.

Here are some examples of RC servo motors

Here is a video of the working principle of normal RC servo motor

There are smart digital servos available in the market. These can give you the current position of servo, speed, torque, temperature, etc as feedback. The digital servos are working by sending/receiving data packets. The control of digital servos is done by sending data packets. One of the examples of digital servos is Dynamixel from ROBOTIS.

1.3.3.4 Stepper Motors: The stepper motors are DC motors that can move in discrete steps. This motor is having multiple sets of coils organized in groups called “phases“. The motor will rotate in each step at a time when you trigger each phase in a sequence. The stepper motors are used where high precision in movement is required.

Here are a few examples of stepper motor you can purchase

Here is a detailed working video of stepper motors.

1.3.3.5 BLDC Motors: BLDC motors are quite popular nowadays and used in many robotic applications. The BLDC motor stands for Brushless DC motor. The main difference between BLDC and DC motors is, ordinary DC motors work using a commutator, which is touching the brushes in the armature, but there is no commutator and brushes in BLDC. Instead of brushes, it uses an electronic commutation.

Here are some examples of BLDC motors that you can purchase

BLDC motors are using in robotics widely, here are some videos which are demonstrating its working.

1.3.3.6 Harmonic Drives: Harmonic drive, which is the brand name of strain wave gear trademarked by Harmonic Drive company and invented in 1957. It is very popular in robotics applications. The working of harmonic drives is demonstrated in the following video

1.3.3.7 Linear DC actuators: These dc motors can convert the DC voltage to linear motion just like pneumatic and hydraulic actuators you have already read. There is a lot of robotic application using linear actuators. Here are some videos to show the working of these motors.

Very nice article for beginners! Thank you ?

Thanks Parthan 🙂

Great explanation and I found the video on harmonic drives very helpful. Thank you for sharing it here. Expecting more

Thanks 🙂